-

admin_slowtextiles / 11 months

- 0

- 2 min read

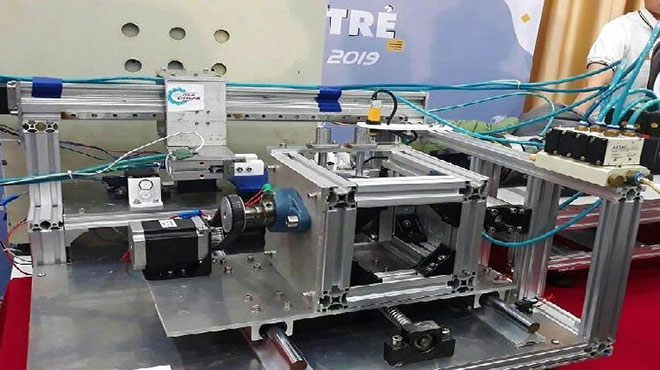

It takes an artisan nearly two months to make a scarf from lotus silk. This is a hard job, especially when taking silk from thousands of lotus stems is very sophisticated. With the aim of improving the productivity while preserving the traditional craft, a group of students from universities in Hanoi have built an automatic lotus machine.

The process of spinning lotus stems to silk thread, is usually done manually. As per estimates, it takes around 3,000 lotus stems to extract 250 gm of lotus silk fibre, and takes around 10 days to weave a scarf. Lotus silk is as light and thin as smoke but it’s quite costly as it needs much labour and artistry.